We’re thrilled to announce our partnership with Vivobarefoot based on BioCirflex3D®

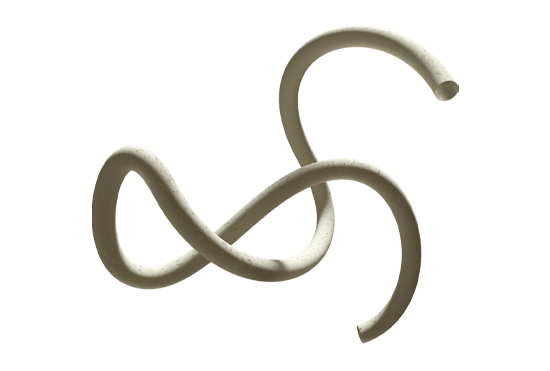

A radical vision for a scan-to-print digital footwear service that reimagines how footwear is designed and made: using biomimetic design principles, additive manufacturing methods, and Balena’s biobased and biodegradable BioCirflex3D® material to produce the first 3D printed and industrially compostable performance shoe.

-

VivoBiome is a vision for a cutting-edge, scan-to-print, circular barefootwear system creating footwear that’s made-to-order, made-to-measure, made locally and made to be re-made. The footwear is made from Balena’s BioCirflex3D®: a bio-based, industrially compostable, recyclable thermoplastic that safely biodegrades at the end of its life.

-

This innovative partnership will unlock a future of on-demand biodegradable footwear that enables you to reconnect to nature, move naturally, and return your footwear back to nature when you’re done, leaving no waste behind.

10,000 years ago, humans made compostable footwear because they had no choice. Today, we’re doing the same.

As featured in

Balena's 3D-printing specific material, BioCirflex3D® , is founded on BioCirFlex® technology, ensuring remarkable flexibility similar to TPU and delivering resilient, long-lasting 3D-printed products. Distinguishing itself, BioCirflex3D® is both biobased and industrially compostable, effectively minimizing the environmental footprint of discarded prints.

This breakthrough allows for the 3D printing of flexible and durable items with the unique attribute of biodegradability, a stark contrast to traditional TPU, which is non-biodegradable and contributes to plastic waste. Consumers can effortlessly return their worn-out footwear to a controlled compost environment reducing environmental impact and contributing to a more circular and sustainable world.