In a world where environmental consciousness is on the rise, consumers and industries are reshaping traditional manufacturing paradigms to align with circular economy principles. Among the most notorious polluters, the footwear industry has been long overdue for a transformation. At Balena, we embarked on a purpose-driven journey to improve this sector and set a new standard for sustainable and circular fashion.

Thus, we set out on an ambitious quest to create a sneaker that is not only functional but also fully compostable, ensuring a positive end-of-life cycle. In this blog, we invite you to join us on our journey of development, research, and design, as we unveil the challenges, triumphs, and innovations that help us bring circularity to life. Together, we'll explore the science behind our materials, the dedication that fueled our efforts, and the collective impact we can make in transforming the footwear industry into a circular powerhouse.

The Footwear Industry - What is the problem?

The footwear industry's impact on the environment has been nothing short of alarming, earning itself a reputation as one of the most polluting sectors globally. 24 billion shoes are added to the market each year, with a staggering 90% of shoes ending up in landfills or are burnt. These massive quantities of shoes produced each year contribute to extensive landfill waste, and the slow decomposition of conventional footwear materials adds to the burden. Adding to the challenge, recycling shoes is complex due to the diverse blend of materials they incorporate. As these discarded shoes pile up in landfills, they often end up being incinerated, releasing harmful pollutants into the atmosphere and exacerbating air pollution. Such unsustainable practices perpetuate a destructive cycle, leaving a substantial carbon footprint and ecological footprint on our planet. It is high time for the industry to take responsibility for its actions and seek transformative solutions to break free from this vicious cycle of waste and pollution. Motivated by the urgent need for transformative solutions in the footwear industry, we embarked on an innovative design, development and research journey to create a fully compostable sneaker, challenging conventional practices and setting new standards for sustainability and circularity.

Our Design & Development Journey

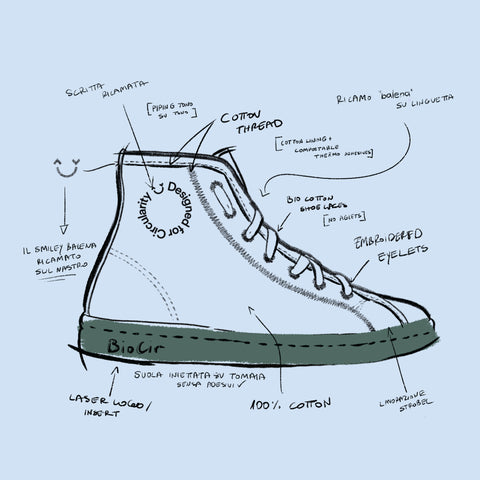

Over the past year, Balena CPO, Yael Joyce Vantu and Head of Research and Development Galy Levy, worked closely together, undertaking an ambitious journey of innovation and circularity. It started off by testing biodegradable materials on monobloc shoes and sandals, finding practical end-of-life solutions for these products. Building on that success, the team moved their focus to the sneaker industry, where they spent the past year researching and exploring alternatives to conventional materials. Balena’s ultimate goal was to create a fully compostable sneaker, replacing harmful components with natural and biodegradable materials. We also sought innovative design solutions to eliminate the reliance on plastics, metals, and glues, crafting a more circular and environmentally-friendly product.

Throughout the design stage, circularity was at the forefront. We minimized material usage, avoided sponges and double linings to reduce waste, and tackled excessive glue usage by adopting the direct injection on the upper method. This technique allowed us to inject BioCir, our biobased biodegradable material, directly onto a natural fiber upper, eliminating the need for glue. Our commitment to sustainability extended to every detail of the sneakers. We replaced metal and plastic eyelets with intricate embroidered details. Additionally, we meticulously designed shoelaces made from natural materials, further reducing reliance on synthetic components. Biodegradable aglets replaced conventional ones, ensuring even the smallest details aligned with our sustainable vision.

The sole was created using our BioCir material, representing a revolutionary step in sustainable footwear innovation. Developed with cutting-edge technology, BioCir is a proprietary biodegradable material created by Balena. Carefully engineered to break down naturally and harmoniously with the environment. With BioCir leading the way in our sole design, we are continuously developing innovations that not only treads lightly on the planet but also elevates sustainability in the footwear industry to a whole new level.

End-of-Life

These sustainable design choices have significant implications for the end-of-life phase of our sneakers and contribute greatly to circularity in the footwear industry. By using biodegradable materials and eliminating harmful components like glues, metals, and plastics, our sneakers can naturally decompose at the end of their lifecycle at industrial compost facilities, reducing the burden on landfills and minimizing environmental pollution. Moreover, the focus on recyclability and biodegradability ensures that our sneakers can be repurposed, closing the loop in the manufacturing process and promoting a more sustainable and responsible approach to consumption and production.

Looking to the future

We are working towards a future where all consumer goods products, across different industries have a clear end of life solution. We are disrupting the material industry through innovating and developing cutting edge circular materials to replace hazardous, polluting, non-compostable plastics currently being used. Together, we can drive change and revolutionize the fashion landscape, making circularity a central pillar of every collaboration moving forward.

Learn more about our material innovations here >>

"

"